The Role of Process Engineering in Rethinking Digital Transformation

Written by Julien de Beer, Head of Portfolio Management, AVEVA

There’s no doubt that the pandemic has highlighted the need to digitize the industrial world, prompting many organizations to re-evaluate their capital projects. The shift to remote working has been monumental, and the speed of adoption and the significant number of workers moving to virtual ways of working has put digital capacities to the test. The desire to stay connected despite a rift in the industry has remained an essential component for continuous productivity.

The crisis has therefore served another purpose, accelerating both the necessity and possibilities of digital collaboration. As supply chains have been seriously impacted, we are now forced to look for alternatives when it comes to being agile and resilient. In light of recent events, results show that 50% of companies have plans to invest in digital transformation and AI in the next three years. Similarly, 66% of manufacturing enterprises from 17 countries now report using cloud implementation. Perhaps, an abrupt change was the sort of trigger that was needed.

Much Needed Change

Digital transformation marks a major rethink in how organizations use technology, people and processes to fundamentally change business performance and strategies. For AVEVA, digital transformation is the most logical answer in moving towards a more streamlined, effortless system in the industrial sector. Some of the most vital sectors which AVEVA works – including energy, oil & gas, food and beverage and marine – had previously been slower to adopt change, with a limited number of automated processes. Nevertheless, these sectors have begun to recognize that this approach is outdated and call for a renovation is needed.

The pace of technological change sweeping across the industry is breath-taking, and it is catapulting organizations towards a new reality with new possibilities. Enterprises are at a crucial new turning point and revitalizing the industry cannot be delayed. In an environment where everyone says they are going digital; the industry will need a new set of rules in order to be successful. Going digital is not only important, but it is becoming the price of admission for doing business.

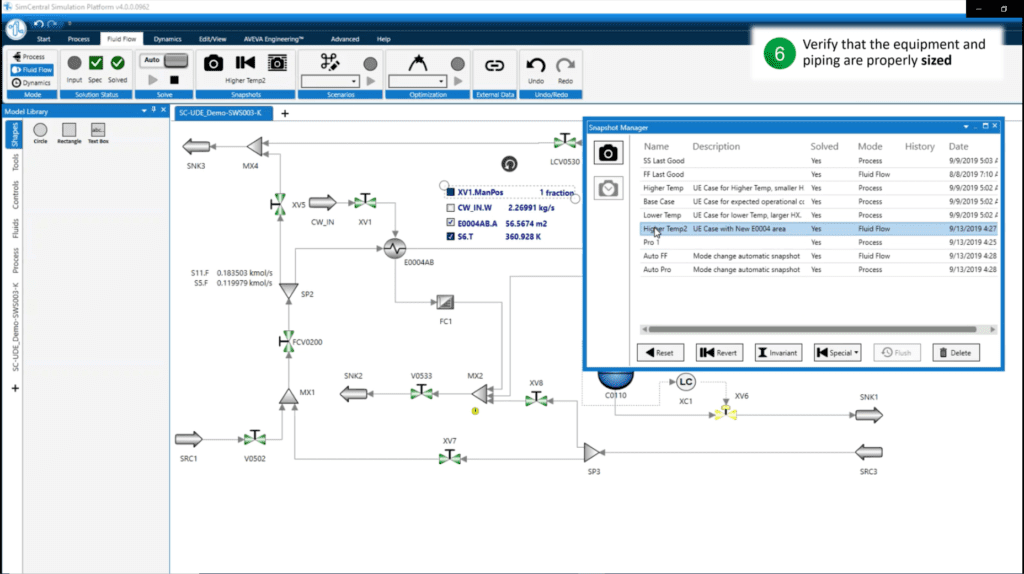

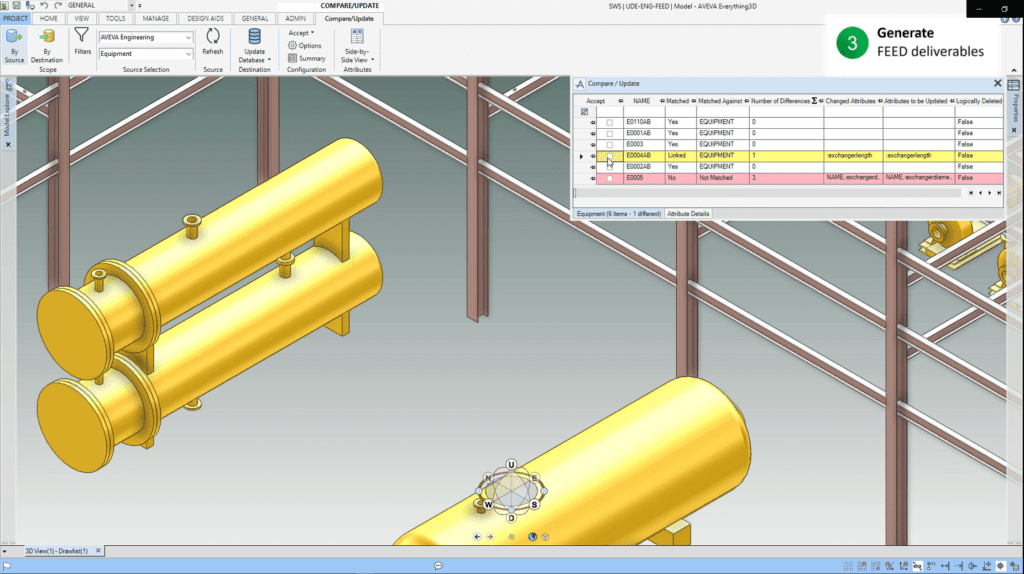

One of the ways that AVEVA ensures that this transformation has a competitive advantage is through AVEVA Unified Engineering. From a single data-hub, this product provides end-to-end integration of conceptual, FEED and detailed design into an environment that handles all process simulation and engineering.

With Unified Engineering, process licensors, EPCs and Operators can enjoy expert and adaptable workflows with advanced collaboration and project control – resulting in 50% faster FEED stage, 30% increase in engineering efficiency and a minimum of 5% Total Installed Cost (TIC) savings in the engineering and design phase alone. Now, multi-discipline teams can collaborate in real-time, increasing engineering efficiency to minimize risk and maximize return on capital investment.

AVEVA Process Simulation

In practice, consumer experience optimization, operational flexibility and innovation are key drivers and goals of digital transformation – with AVEVA Process Simulation, achieving this is easy.

AVEVA Process Simulation is an innovative, integrated platform covering the entire process engineering lifecycle of design, simulation and training. Being the first commercially available platform to take advantage of web-based and cloud technologies, it provides an enjoyable and interactive user capability. In turn, this will increase productivity, creativity and collaboration. No longer are users faced with out-dated models, but a visible, cooperative experience.

The principal aims for creating this unique solution was to breakdown the silos and historical limitations in process simulation and design. In a transforming world, engineering managers must respond to changing conditions while onboarding and providing a pathway for the new generation of engineers. AVEVA Process Simulation is designed from the ground up to deliver this momentum – providing the benefits of digital transformation.

The Modern Approach to Engineering Projects

Overall, AVEVA Unified Engineering provides our customers with an opportunity to gain a competitive edge towards digital transformation. With this process, multidiscipline engineers can achieve faster completion of deliverables with greater transparency and higher accuracy. By utilizing AVEVA Unified Engineering in the digital age, the quality and reliability of engineering deliverables will be enhanced as we see reductions in cost.