Safeguarding your Plant Automation Systems with Change Management (Auvesy versiondog blog)

Learn about data management best practices to improve your plant automation processes

A change management system is a way of creating a consistent, systematic way to manage, monitor, and document the changes made to your plant’s automation systems. By standardizing and centralizing the change processes in your plant, you can streamline your automation-related data management tasks significantly. This can quickly improve your plant automation performance and reduce downtime caused by human error, unplanned maintenance, cyber attack and more.

How can a change management software safeguard your plant automation systems?

Centralize your Project Data

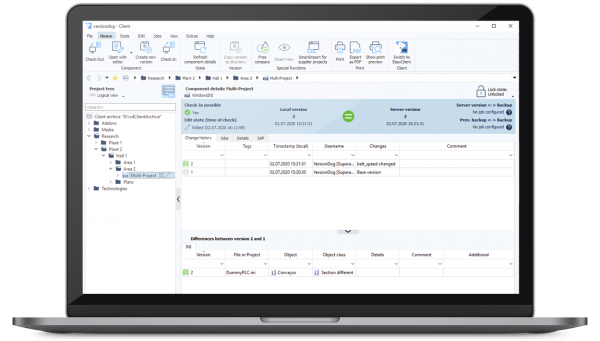

Do you really know where the latest project version is stored for every automated device in your facility? If you’re relying on your staff to diligently follow naming and saving conventions independently, you’re taking a bigger risk than you might think. Change management software like versiondog centrally stores project data while managing access. This way, you protect your automation layer while gaining greater visibility. With centralized data storage, you can quickly locate the data you need and be confident that you’re always working with the correct version.

Monitor WHO Changed WHAT, WHEN, WHERE, and WHY

Change is an inevitable reality of the production process whether it be to optimize output, make process adjustments, or fix a quality issue. These changes often need to be made urgently, opening the door to a greater possibility for human error and a lack of proper documentation.

How confident are you that the changes being made in your facility are adequately tracked and documented? A change management system like versiondog can compare the version running on each automated device with the version stored on the server, ensuring that you never overlook a change again. Metadata like the user ID and timestamp are automatically documented and users are required to input a brief change reason to check-in a new project version. This guarantees that change history is complete and accurate for every single automated device in your plant. This change monitoring also allows you to detect unauthorized changes like cyber attacks before they cause significant damage to your plant automation.

Save time and Effort with Automatic Backups

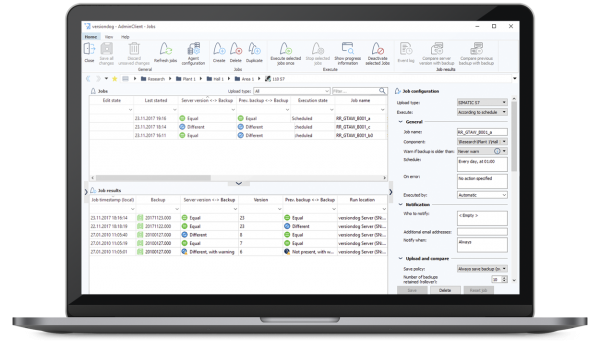

How often are you backing up plant automation data? When backups are done manually, you are opening your plant automation up to the risk of human error. What if a device is overlooked? What if the backups are not stored in the correct location? What if your team has run out of time or can’t be physically at the plant for one reason or another?

Manual backups are unnecessarily time-consuming and mundane. With a data management system like versiondog, you can automate backups for a wide variety of plant automation systems so that you can spend more time on more important tasks. These backups can also be used for smart comparisons so that you never overlook a change again. versiondog can even help you simplify data management efforts for non-networked devices.

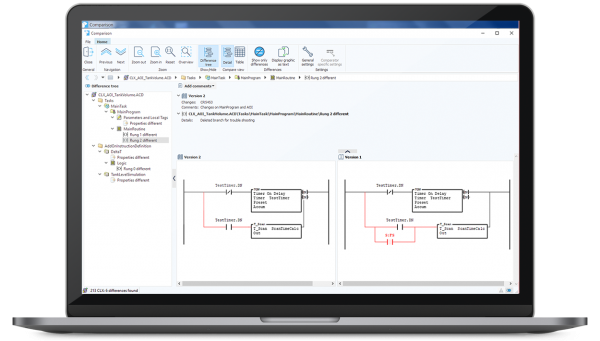

Graphically Compare Versions

With versiondog, you can quickly and easily detect even the smallest difference between two project versions. For many devices, versiondog can graphically display these differences saving you time and effort in the process. These smart compares help you to restore the correct project version during disaster recovery or revert to error-free versions when needed.

Easily Prepare for Audits

A major aspect of change management for plant automation is documentation. To adequately prepare for audits, changes should be thoroughly and consistently documented. For many, this is a daunting and time-consuming process. With a change management system, the documentation you need for audit trails can be generated with the click of a button.

versiondog is a fast and reliable version control and automatic backup software for plant automation. Learn more about how you can safeguard your plant automation systems today.