7 Ways to Accelerate Predictive Analytics Time to Value

Predictive analytics collects and analyzes real-time asset data to predict and prevent potential problems on the factory floor by alerting workers to developing issues. Instead of shutting down equipment immediately, situations can be proactively assessed for more convenient outcomes. Maintenance costs can be reduced due to better planning, parts can be ordered and shipped without rush, and equipment can continue running.

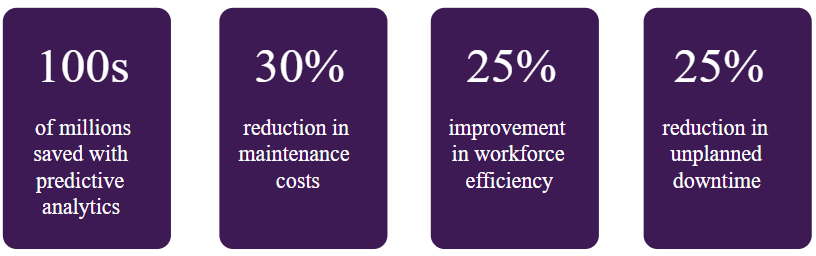

Organizations that implement predictive analytics experience hundreds of millions of dollars saved in early warning catches, 30% reduction in maintenance costs, 25% improvement in workforce efficiency, and 25% reduction in unplanned downtime. Many managers see the value in predictive analytics. Verdantix reported that 37% of the 259 operations, maintenance, engineering, and process safety managers they surveyed plan to invest in software for asset failure prediction in 2021. And yet, the commitment to implement predictive analytics seems daunting for many.

Implementing predictive analytics doesn’t have to be complicated or overwhelming. If you’re looking to simplify your predictive analytics implementation, then I highly suggest you consider a predictive analytics solution in the Cloud. Let’s take a look at some of the qualities of a best of breed predictive analytics solution in the Cloud.

7 Best of Breed Predictive Analytics Features that Accelerate Your Time to Value

1. No-Touch Administration

There are several administration benefits to deploying predictive analytics as a Managed Software-as-a-Service (SaaS) application. For one, there is no software to install on client computers; simply leverage an Internet browser. Workers benefit from seamless, automatic updates to predictive analytics software without burdening IT since the service provider manages the software. As a result, no additional IT infrastructure or staffing is required as you scale your predictive analytics application up or down to meet your business needs.

2. Equipment Agnostic

Look for predictive analytics software that is equipment agnostic. The software should be able to monitor assets regardless of equipment type, vendor, or asset age without the need for manufacturer specific asset information. Extensive asset strategy libraries contain numerous templates of the most commonly used asset types and components to deliver a quality asset strategy sooner and with less effort. This flexibility delivers more information about the health and performance of your equipment than ever before. Your predictive analytics solution will have the ability to rapidly transform raw data across the factory into actionable insights to prevent equipment failure and make smart decisions that improve operations.

3. Scalable Solution

Choose a predictive analytics system that is highly scalable and can be used to monitor a single asset, a specific plant, or thousands of remote assets across multiple sites. A highly scalable solution allows you to scale up or down to adjust to dynamic business needs or economic conditions with the right tools at the right time.

4. Break Down IT Silos

The best predictive analytics solutions integrate data from a wide variety of data historians, control, and monitoring systems into a central location. The flexible integration of a range of data sources eliminates IT silos so the organization can leverage all of its data to improve user engagement.

5. No Programming Required

Your organization doesn’t have a data scientist or software programmer. No problem. The best of breed predictive analytics applications are easy to use with intuitive, graphically driven model building processes that take minutes (instead of hours) to learn. No programming or equipment knowledge required. No software code to maintain. A solution that includes a variety of templates and a database of known assets and conditions streamlines the model-building process even further, making it simple for users to create and maintain their own models.

6. Flexibility to Extend Your System

Find a predictive analytics solution that can easily integrate its results with other business systems through web services and APIs. Solutions that are designed to be extensible take your unique business needs and future growth into consideration by anticipating the need to add new functionality or exchange data with other systems.

7. Employee Empowerment

The ability to securely view predictive analytics data on a browser or mobile device, like a smartphone or tablet, empowers users with the ability to monitor the performance of critical assets on the go or from a remote location. Users can view and analyze data and alerts from their mobile device—anywhere, anytime—and follow up with prescriptive actions.

The Proof is in Performance

When predictive analytics are part of your Maintenance Strategy, workers know and understand the actual and expected performance for an asset’s current operational state. They know where inefficiencies are and can use this information to understand the impact of performance deficiencies on current and future operations. This information helps assess the risk and potential consequences associated with each monitored asset and can be used to better prioritize capital and operational expenditures.

Industry-leading predictive analytics applications in the Cloud deliver cost-effective software-as-a-service (SaaS) solutions that are simple to set-up, manage, and use without additional IT infrastructure or staffing. Predictive analytics in the Cloud enables you to quickly turn the data sitting in new and existing industrial assets and processes into a live information feed for decision support.

Enjoy seamless, automatic updates and scalability for your business needs. Translate time-series data into intuitive charts and dashboards. Enable faster, more informed decision making for all users, with up-to-date newsfeeds, intelligence, and alerts.